MRP End Assembly Pegging

Description:

Detail report for MRP pegging from final assembly to each component, including: planner, end demand pegged qty, demand and plan dates, supply quantity, and supply date.

Parameters

Organization Code, Plan, End Assembly, Component, Supplier, Planner, Buyer, Make or Buy, End-Assembly Pegging Only

Used tables

oe_sets, mtl_parameters, mrp_full_pegging, mtl_system_items_vl, mtl_units_of_measure_tl, per_people_x, mtl_planners, fnd_lookup_values, mrp_recommendations, mrp_item_purchase_orders, wip_entities, wip_discrete_jobs, mrp_gross_requirements, oe_order_lines_all, oe_order_headers_all, oe_transaction_types_tl

Categories

Related reports

MRP Pegging, PO Headers and Lines

Dependencies

If you would like to try one of these Oracle EBS SQLs without having Blitz Report installed, note that some of the reports require functions from utility package xxen_util.

Example Report

MRP End Assembly Pegging 20-Jan-2019 031236.xlsx

Report SQL

www.enginatics.com/reports/mrp-end-assembly-pegging/

Blitz Report™ import options

MRP End Assembly Pegging - Case Study & Technical Analysis

Executive Summary

The MRP End Assembly Pegging report provides a critical link between component supply and final product demand. It traces the requirement for a specific component all the way up the Bill of Materials (BOM) to the final “End Assembly” (finished good) that is driving that demand. This visibility is essential for prioritizing component allocation during shortages.

Business Challenge

In a complex manufacturing environment, a single raw material (e.g., a specific screw or chip) might be used in dozens of different finished products. When that raw material is in short supply, planners need to know:

- Impact Analysis: “If this shipment of screws is delayed, which customer orders for finished computers will be missed?”

- Prioritization: “We only have enough chips for 50 units. Should we build Product A (high margin) or Product B (strategic customer)?”

- Expediting: “Why is the system telling me to buy this part today? Is it for a rush order?”

Solution

The MRP End Assembly Pegging report solves this by “pegging” (linking) supply to demand.

Key Features:

- Full Traceability: Shows the path from the component, through sub-assemblies, to the final end item.

- Demand Context: Identifies the specific Sales Order or Forecast that is driving the need.

- Schedule Alignment: Compares the supply date (when the part is available) with the demand date (when the finished good is needed).

Technical Architecture

The report relies on the MRP Pegging logic, which is calculated during the planning run.

Key Tables and Views

MRP_FULL_PEGGING: The core table storing the links between supply and demand.MRP_RECOMMENDATIONS: Stores the planned orders generated by the MRP engine.MRP_GROSS_REQUIREMENTS: Stores the independent demand (Sales Orders, Forecasts).WIP_DISCRETE_JOBS: Represents the work orders that consume the materials.

Core Logic

- Pegging Traversal: The report starts with the component supply (e.g., a Purchase Order or Planned Order).

- Upstream Navigation: It recursively traverses the

MRP_FULL_PEGGINGtable to find the parent demand. - End Item Identification: It stops when it reaches an independent demand source (Sales Order or Forecast) at the top of the BOM structure.

Business Impact

- Strategic Allocation: Enables data-driven decisions on how to allocate scarce materials to the most important customer orders.

- Customer Service: Allows customer service reps to proactively notify customers of potential delays based on component shortages.

- Inventory Optimization: Helps identify “orphan” supply that is no longer pegged to any valid demand, allowing for cancellation or deferral.

Oracle E-Business Suite Reporting Library

We provide an open source Oracle EBS SQLs as a part of operational and project implementation support toolkits for rapid Excel reports generation.

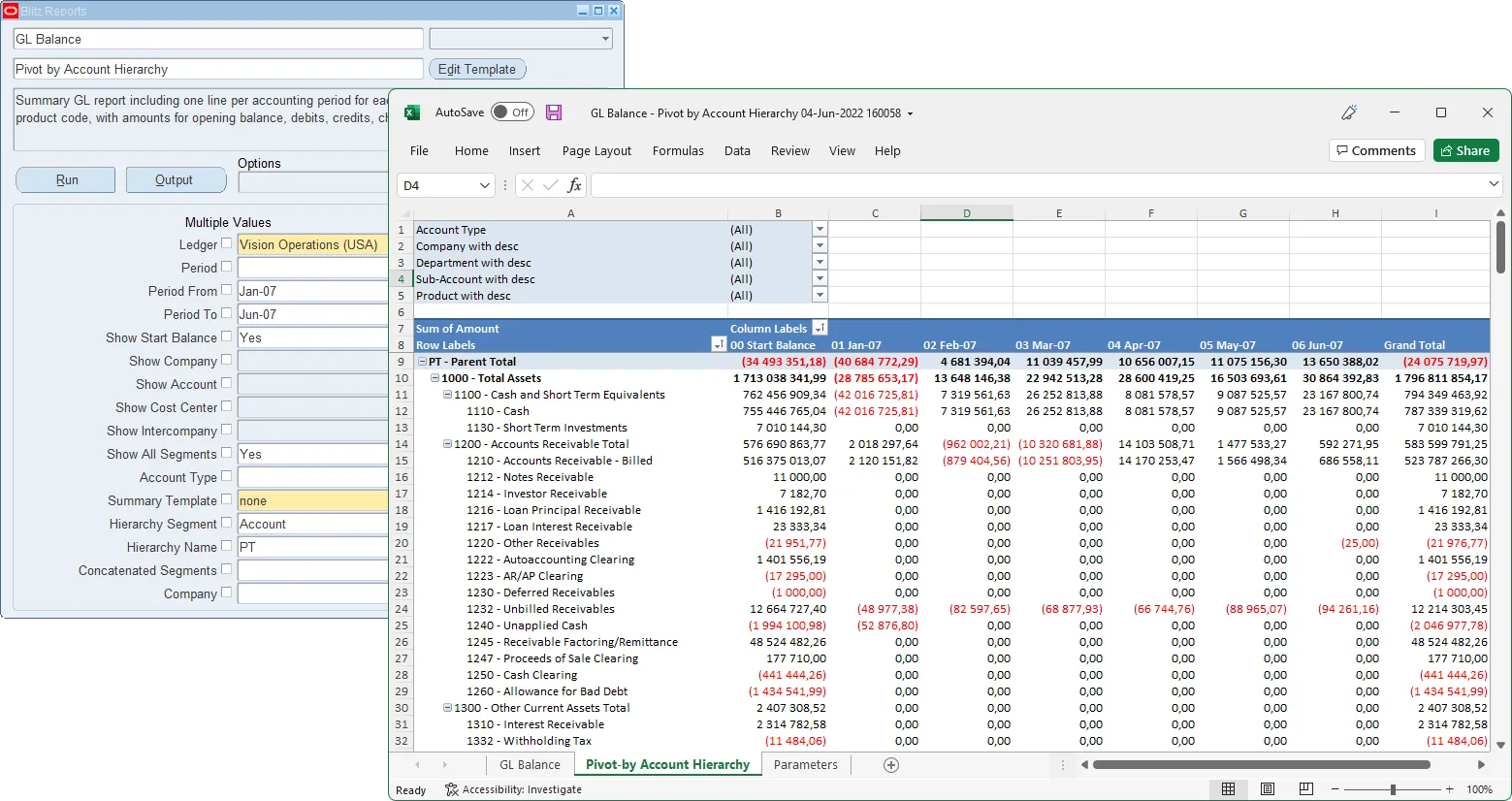

Blitz Report™ is based on Oracle EBS forms technology, and hence requires minimal training. There are no data or performance limitations since the output files are created directly from the database without going through intermediate file formats such as XML.

Blitz Report can be used as BI Publisher and Oracle Discoverer replacement tool. Standard Oracle BI Publisher and Discoverer reports can also be imported into Blitz Report for immediate output to Excel. Typically, reports can be created and version tracked within hours instead of days. The concurrent request output automatically opens upon completion without the need for re-formatting.

The Filters, Columns, Rows and Values fields are used to create and deliver the data in pivot table format with full drill down to details.

The Excel template upload functionality in Blitz Report allows users to create their own layouts by uploading an Excel template with additional sheets and charts, automatically refreshed when the report runs again. This allows to create custom dashboards and more advanced visualizations of report data.

You can download and use Blitz Report free of charge for your first 30 reports.

The installation and implementation process usually takes less than 1 hour; you can refer to our installation and user guides for specific details.

If you would like to optimize your Oracle EBS implementation and or operational reporting you can visit www.enginatics.com to review great ideas and example usage in blog. Or why not try for yourself in our demo environment.

Useful Links

Blitz Report™ – World’s fastest data upload and reporting for Oracle EBS

Oracle Discoverer replacement – importing worksheets into Blitz Report™

Blitz Report™ Questions & Answers

Supply Chain Hub by Blitz Report™

© 2025 Enginatics