WIP Outside Processing

Description:

Imported from BI Publisher Description: WIP Outside Processing Report Application: Work in Process Source: WIP Outside Processing Report (XML) Short Name: WIPLBOSP_XML DB package: WIP_WIPLBOSP_XMLP_PKG

Parameters

Organization Code, Jobs/Schedules From, Jobs/Schedules To, Assembly From, Assembly To, Lines From, Lines To, Status, Open POs Only

Used tables

mtl_parameters, mtl_system_items_vl, po_headers_all, mtl_units_of_measure, po_lines_all, po_line_locations_all, po_distributions_all, ap_suppliers, hz_parties, po_releases_all, mtl_employees_view, bom_resources, hr_organization_information, wip_entities, wip_discrete_jobs, org_access_view, wip_repetitive_schedules, wip_repetitive_items, wip_lines

Categories

Dependencies

If you would like to try one of these Oracle EBS SQLs without having Blitz Report installed, note that some of the reports require functions from utility package xxen_util.

Example Report

WIP Outside Processing 09-May-2025 220559.xlsx

Report SQL

www.enginatics.com/reports/wip-outside-processing/

Blitz Report™ import options

Case Study & Technical Analysis: WIP Outside Processing Report

Executive Summary

The WIP Outside Processing report is a crucial operational and financial monitoring tool for Oracle Work in Process (WIP), specifically designed to track manufacturing operations performed by external suppliers. It provides a consolidated view of all outside processing activities, linking WIP jobs to their corresponding purchase orders, receipt transactions, and supplier details. This report is indispensable for production managers, procurement teams, and cost accountants to ensure timely completion of outsourced operations, manage supplier performance, control costs, and maintain accurate inventory and WIP valuations.

Business Challenge

Many manufacturing processes involve sending components or sub-assemblies to external suppliers for specialized operations (e.g., plating, heat treatment). Managing these outside processing (OSP) operations presents several challenges:

- Lack of End-to-End Visibility: Tracking materials sent to a vendor for OSP, monitoring the progress of the outsourced work, and receiving the finished components back into WIP is often fragmented across multiple Oracle modules (WIP, Purchasing, Receiving).

- Monitoring Supplier Performance: Without a consolidated view, it’s difficult to assess the on-time performance of OSP suppliers, identify delays, or manage supplier capacity effectively.

- Cost Control and Reconciliation: Ensuring that OSP costs are correctly incurred and applied to the WIP job, and reconciling these costs with supplier invoices, is a complex financial control point.

- Operational Bottlenecks: Delays in OSP can halt internal production lines, impacting overall manufacturing schedules and customer delivery commitments. Identifying these bottlenecks proactively is critical.

- Audit Trail: For compliance and financial audits, a clear record of all OSP activities, including associated POs, receipts, and costs, is essential.

The Solution

This report offers a powerful, integrated, and actionable solution for managing outside processing operations, bringing transparency and control to outsourced manufacturing.

- Unified OSP View: It links WIP jobs and schedules directly to their outside processing purchase orders (POs), PO lines, receipts, and supplier information, providing a complete end-to-end view of the outsourced process.

- Status Monitoring: The report allows users to monitor the

Statusof OSP jobs and associated POs, helping to identify items withOpen POs Onlythat are still awaiting completion or receipt from the supplier. - Supplier Performance Tracking: By consolidating supplier and item details with delivery and cost information, the report helps assess OSP supplier performance, identifying those who consistently deliver on time and within budget.

- Accelerated Troubleshooting: When delays occur, the report provides immediate access to relevant PO, supplier, and job details, enabling production and procurement teams to quickly investigate the root cause and expedite necessary actions.

Technical Architecture (High Level)

The report queries core Oracle Work in Process, Purchasing, and Inventory (Receiving) tables to consolidate outside processing data.

- Primary Tables Involved:

wip_entitiesandwip_discrete_jobs(for WIP job and schedule details).po_headers_all,po_lines_all,po_line_locations_all,po_distributions_all(for Purchase Order details associated with OSP).rcv_transactions(for receipt transactions against OSP POs).mtl_system_items_vl(for item master details of assemblies and components).ap_suppliersandhz_parties(for supplier information).bom_resources(for identifying outside processing resources).

- Logical Relationships: The report identifies WIP jobs that include outside processing resources. It then links these WIP jobs to the corresponding Purchase Order headers, lines, schedules, and distributions (

po_headers_all,po_lines_all,po_line_locations_all,po_distributions_all) that were created to procure the OSP service. Further joins torcv_transactionstrack the receipt of the completed components from the supplier, andap_suppliersprovides supplier details, giving a comprehensive view of each OSP event.

Parameters & Filtering

The report offers extensive parameters for precise filtering and detailed data inclusion:

- Organizational Context:

Organization Codefilters the report to a specific manufacturing organization. - Job and Item Identification:

Jobs/Schedules From/To,Assembly From/To,Lines From/Toallow for granular targeting of specific production orders or manufactured items. - Status Filters:

Status(for WIP job status) andOpen POs Only(to focus on outstanding orders with OSP suppliers) are crucial for operational monitoring.

Performance & Optimization

As a transactional report integrating data across multiple modules, it is optimized through strong filtering and efficient joining strategies.

- Parameter-Driven Efficiency: The use of

Organization Code,Jobs/Schedules From/To,Assembly From/To, and theOpen POs Onlyfilter is critical for performance, allowing the database to efficiently narrow down the large transactional datasets to relevant OSP activities using existing indexes. - Indexed Joins: Queries leverage standard Oracle indexes on

wip_entity_id,organization_id,po_header_id,po_line_id, anditem_idfor efficient data retrieval across WIP, Purchasing, and Inventory tables.

FAQ

1. What is ‘Outside Processing’ in Oracle WIP? Outside Processing refers to manufacturing operations that are performed by an external supplier rather than internally within the plant. These operations are often defined as resources on a WIP routing, and a purchase order is automatically generated to the supplier to procure that service.

2. How does this report help track the progress of items sent to OSP vendors?

By linking the WIP job to the po_headers_all and rcv_transactions tables, the report allows users to see when a purchase order for the OSP service was created, and, crucially, when the completed components were received back into inventory. This provides a clear indication of the progress of outsourced operations.

3. Can this report identify if an OSP item is overdue from the supplier?

Yes. By examining the Need By Date (from the PO line location) and comparing it to the current date for OSP items with Open POs Only and no corresponding receipt in rcv_transactions, procurement and production teams can identify which outsourced items are past due from the supplier, enabling proactive expediting.

Oracle E-Business Suite Reporting Library

We provide an open source Oracle EBS SQLs as a part of operational and project implementation support toolkits for rapid Excel reports generation.

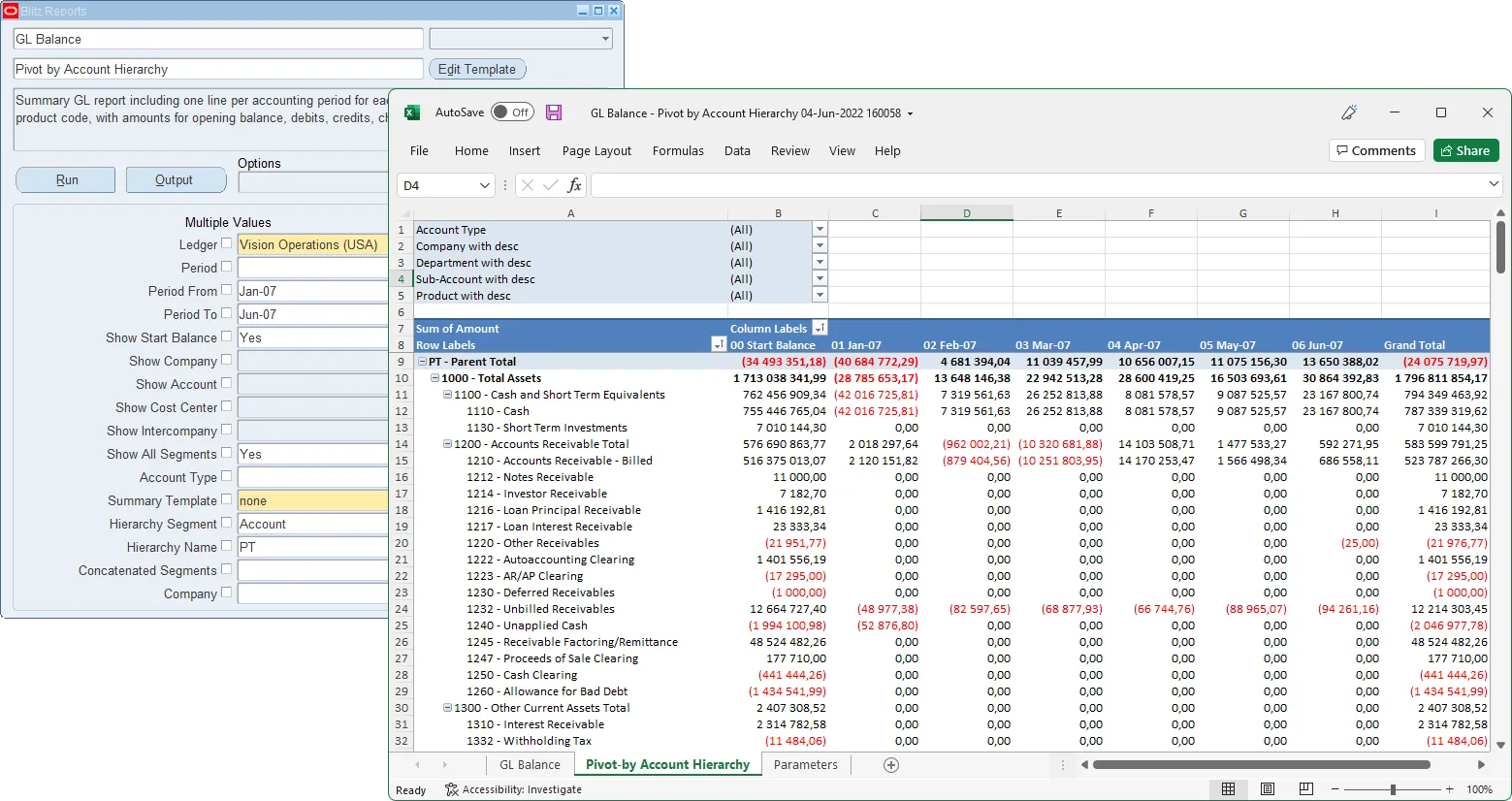

Blitz Report™ is based on Oracle EBS forms technology, and hence requires minimal training. There are no data or performance limitations since the output files are created directly from the database without going through intermediate file formats such as XML.

Blitz Report can be used as BI Publisher and Oracle Discoverer replacement tool. Standard Oracle BI Publisher and Discoverer reports can also be imported into Blitz Report for immediate output to Excel. Typically, reports can be created and version tracked within hours instead of days. The concurrent request output automatically opens upon completion without the need for re-formatting.

The Filters, Columns, Rows and Values fields are used to create and deliver the data in pivot table format with full drill down to details.

The Excel template upload functionality in Blitz Report allows users to create their own layouts by uploading an Excel template with additional sheets and charts, automatically refreshed when the report runs again. This allows to create custom dashboards and more advanced visualizations of report data.

You can download and use Blitz Report free of charge for your first 30 reports.

The installation and implementation process usually takes less than 1 hour; you can refer to our installation and user guides for specific details.

If you would like to optimize your Oracle EBS implementation and or operational reporting you can visit www.enginatics.com to review great ideas and example usage in blog. Or why not try for yourself in our demo environment.

Useful Links

Blitz Report™ – World’s fastest data upload and reporting for Oracle EBS

Oracle Discoverer replacement – importing worksheets into Blitz Report™

Blitz Report™ Questions & Answers

Supply Chain Hub by Blitz Report™

© 2025 Enginatics