WIP Required Components

Description:

Detailed project WIP report that lists discrete jobs and required components. The parameter ‘Show Shortage List’ can be used to show a shortage list of existing discrete jobs (similar to Oracle’s ‘Discrete Job Shortage Report’.

Parameters

Organization Code, Scheduled Start Date From, Scheduled Start Date To, Job, Job Status, Date Required to, Show Shortage List, Project, Assembly, Component, Show Phantom Components, MRP Net

Used tables

org_organization_definitions, wip_entities, mtl_reservations, mtl_sales_orders, wip_discrete_jobs, wip_lines, mtl_system_items_vl, bom_departments, wip_schedule_groups, pa_projects_all, wip_requirement_operations, bom_components_b, mtl_units_of_measure_tl, mtl_item_locations_kfv, mtl_planners, per_people_x, mtl_onhand_quantities_detail, mtl_secondary_inventories, org_access_view

Categories

Dependencies

If you would like to try one of these Oracle EBS SQLs without having Blitz Report installed, note that some of the reports require functions from utility package xxen_util.

Example Report

WIP Required Components 17-Nov-2020 002450.xlsx

Report SQL

www.enginatics.com/reports/wip-required-components/

Blitz Report™ import options

Case Study & Technical Analysis: WIP Required Components Report

Executive Summary

The WIP Required Components report is a critical manufacturing planning and shortage analysis tool for Oracle Work in Process (WIP). It provides a detailed listing of all components required for discrete jobs, along with their on-hand quantities and any potential shortages. This report is indispensable for production planners, material managers, and shop floor supervisors to manage material availability, identify component shortages proactively, ensure timely order fulfillment, and prevent production delays, thereby optimizing manufacturing efficiency and inventory utilization.

Business Challenge

Ensuring that all required components are available at the right time and place for manufacturing jobs is a fundamental challenge in production planning. Organizations often face significant hurdles:

- Material Shortages: Unexpected component shortages can halt production lines, leading to missed delivery dates, increased costs (e.g., expediting fees), and customer dissatisfaction. Identifying these shortages proactively is crucial.

- Lack of Component Visibility: While Bill of Materials (BOM) define components, getting a consolidated view of all required components for all active jobs, combined with their current inventory status, is difficult with standard Oracle forms.

- Inefficient Shortage Identification: Manually comparing required components against on-hand inventory for numerous jobs is a time-consuming and error-prone process, making it difficult to prioritize material procurement efforts.

- Impact of Phantom Assemblies: Phantom components (assemblies that are consumed and never stocked) add another layer of complexity, as their sub-components must also be tracked and available.

- Integration with Planning Systems: Reconciling material needs from WIP with recommendations from Material Requirements Planning (MRP) systems is essential for robust material planning.

The Solution

This report offers a powerful, detailed, and actionable solution for managing required components and identifying shortages in WIP, enhancing production planning and material control.

- Comprehensive Component Listing: It provides a detailed list of all components required for discrete jobs, including item details, quantities required, and their current on-hand availability.

- Proactive Shortage Identification: The

Show Shortage Listparameter is a key feature, transforming the report into a powerful tool that explicitly flags components for which there is insufficient on-hand quantity to meet job demand, similar to Oracle’s standard ‘Discrete Job Shortage Report’. - Visibility into Phantom Components: The

Show Phantom Componentsparameter allows users to “explode” phantom assemblies within the BOM, revealing the lowest-level components actually needed, which is critical for accurate material planning. - Integrated Inventory Data: By linking directly to on-hand inventory, reservations, and sales orders, the report provides a real-time picture of material availability against current production demand.

- Supports Project Manufacturing: The inclusion of

ProjectandTaskparameters enables material planning and shortage analysis for project-specific manufacturing jobs.

Technical Architecture (High Level)

The report queries core Oracle Work in Process, Inventory, and Bills of Material tables to identify required components and assess their availability.

- Primary Tables Involved:

wip_discrete_jobsandwip_entities(for WIP job details).wip_requirement_operations(the central table defining components required for a job’s operations).mtl_system_items_vl(for item master details of both assemblies and components).bom_components_b(for Bill of Material structure, used to explode phantoms).mtl_onhand_quantities_detail(for current on-hand inventory balances).mtl_reservationsandmtl_sales_orders(to account for reserved inventory or sales order demand).pa_projects_all(for project context).

- Logical Relationships: The report starts with

wip_discrete_jobsto identify active manufacturing jobs. It then links towip_requirement_operationsto find the required components for each job. For each component, it queriesmtl_onhand_quantities_detailto get the current inventory. TheShow Shortage Listlogic performs a calculation to determine if (Required Quantity - On-Hand Quantity) > 0. TheShow Phantom Componentsparameter involves recursive joins throughbom_components_bto identify components of phantom assemblies.

Parameters & Filtering

The report offers an extensive set of parameters for precise filtering and detailed data inclusion:

- Organizational Context:

Organization Codefilters the report to a specific manufacturing organization. - Job and Assembly Identification:

Job,Assembly,Componentallow for granular targeting of specific production orders or items. - Date Ranges:

Scheduled Start Date From/ToandDate Required toare crucial for analyzing material needs for jobs scheduled within specific periods or requiring components by a certain date. - Status and Shortage Flags:

Job StatusandShow Shortage Listare vital for focusing on active or problematic jobs and directly identifying material shortfalls. - BOM/Planning Options:

Show Phantom ComponentsandMRP Net(if applicable) provide advanced control over how the BOM is exploded and how inventory is considered in the shortage calculation. - Project Filter:

Projectallows for focusing on jobs linked to a particular project.

Performance & Optimization

As a detailed transactional report integrating data across multiple modules (WIP, Inventory, BOM), it is optimized through strong filtering and efficient joining strategies.

- Parameter-Driven Efficiency: The use of

Organization Code,Scheduled Start Dateranges,Job,Assembly, andComponentfilters is critical for performance, allowing the database to efficiently narrow down the large transactional datasets to relevant WIP jobs and their components using existing indexes. - Conditional Shortage Calculation: The

Show Shortage Listparameter triggers the shortage calculation only when explicitly requested, preventing unnecessary processing for a full component list. - Indexed Joins: Queries leverage standard Oracle indexes on

wip_entity_id,organization_id,inventory_item_id,component_item_id, andproject_idfor efficient data retrieval across WIP, Inventory, BOM, and Projects tables.

FAQ

1. What is the significance of the ‘Date Required to’ parameter?

The Date Required to parameter allows you to specify a cutoff date. The report will then identify shortages for all components that are required by or before that date. This is crucial for prioritizing material procurement and expediting efforts based on immediate production needs.

2. How does the report calculate the ‘Shortage List’?

The report calculates a shortage by comparing the Quantity Required for a component on a WIP job against its currently Available On-Hand Quantity (which may also factor in existing reservations or future supply, depending on the MRP Net parameter). If Quantity Required > Available On-Hand, a shortage is identified and typically flagged with the deficit amount.

3. Can this report help identify components that are needed for multiple jobs?

Yes. By running the report for a broad range of Jobs and then analyzing the Component column, users can identify common components that are required across multiple production orders. This insight is valuable for consolidating material procurement or identifying high-demand components that might become bottlenecks.

Oracle E-Business Suite Reporting Library

We provide an open source Oracle EBS SQLs as a part of operational and project implementation support toolkits for rapid Excel reports generation.

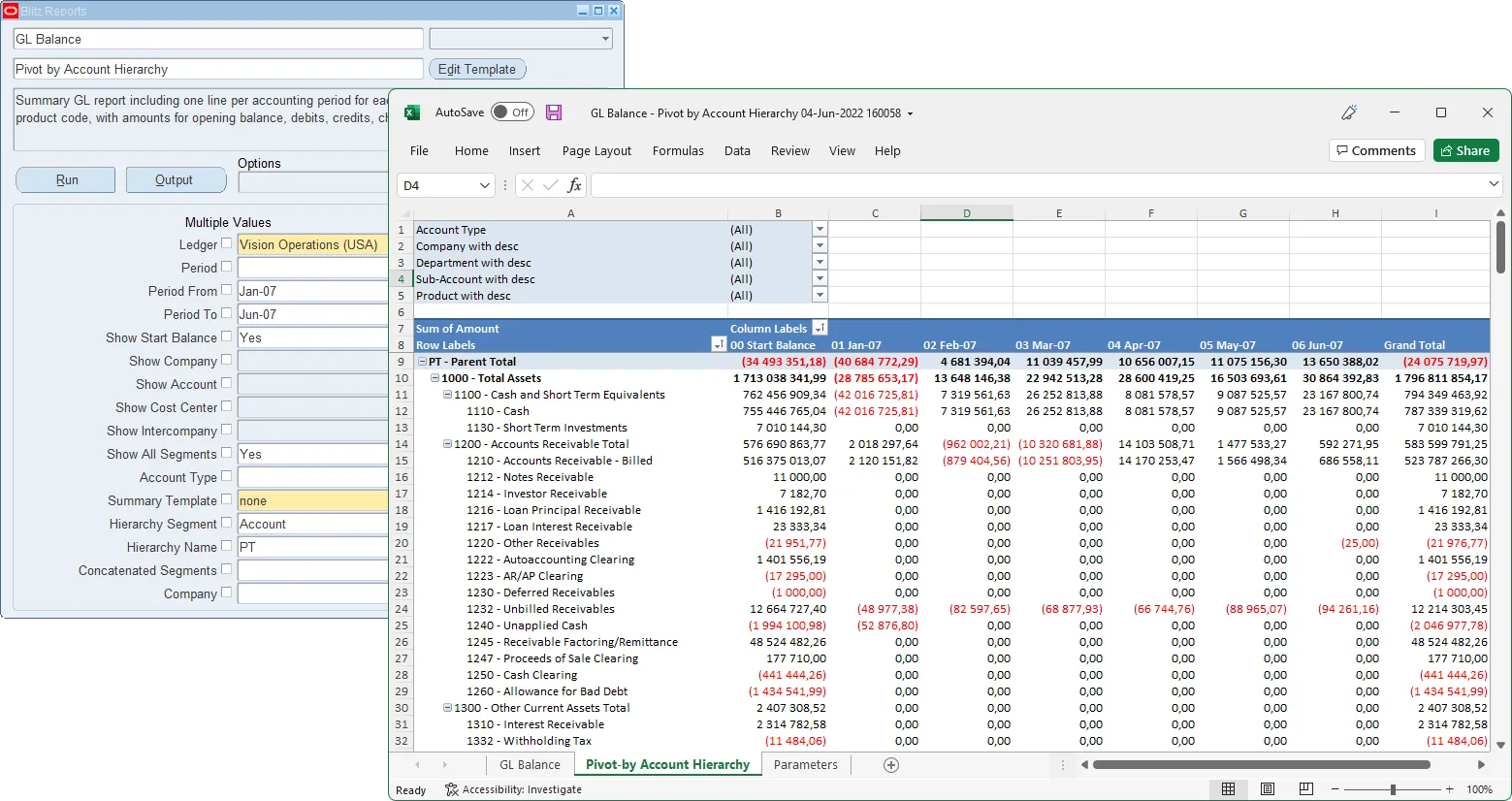

Blitz Report™ is based on Oracle EBS forms technology, and hence requires minimal training. There are no data or performance limitations since the output files are created directly from the database without going through intermediate file formats such as XML.

Blitz Report can be used as BI Publisher and Oracle Discoverer replacement tool. Standard Oracle BI Publisher and Discoverer reports can also be imported into Blitz Report for immediate output to Excel. Typically, reports can be created and version tracked within hours instead of days. The concurrent request output automatically opens upon completion without the need for re-formatting.

The Filters, Columns, Rows and Values fields are used to create and deliver the data in pivot table format with full drill down to details.

The Excel template upload functionality in Blitz Report allows users to create their own layouts by uploading an Excel template with additional sheets and charts, automatically refreshed when the report runs again. This allows to create custom dashboards and more advanced visualizations of report data.

You can download and use Blitz Report free of charge for your first 30 reports.

The installation and implementation process usually takes less than 1 hour; you can refer to our installation and user guides for specific details.

If you would like to optimize your Oracle EBS implementation and or operational reporting you can visit www.enginatics.com to review great ideas and example usage in blog. Or why not try for yourself in our demo environment.

Useful Links

Blitz Report™ – World’s fastest data upload and reporting for Oracle EBS

Oracle Discoverer replacement – importing worksheets into Blitz Report™

Blitz Report™ Questions & Answers

Supply Chain Hub by Blitz Report™

© 2025 Enginatics